Application: mainly used for deep deoxygenation of high pressure boiler.

Dosage: 2~10 g/m³ water supply

[Index]

Appearance: Colorless transparent or amber liquid

pH value: 6.0~9.0

Density :≥0.85

[Method of use]

Using the products of our company, our company has professional personnel to the site to install and debug the special equipment on the spot. According to the different use conditions, our company formulates a complete use plan and trains the operators. Generally, boiler water supply is adjusted to 1% aqueous solution and injected into the water supply system with metering pump.

Safety protection: KR-902 deaerator product operation without special requirements, inadvertently into the eye or contaminated skin can be cleaned with clean water. High ph value products have a certain alkalinity, should pay attention to labor protection, must wear goggles and acid-alkali gloves, inadvertently into the eyes or contaminated with skin, immediately with a large amount of flowing water rinse.

[Package & Storage]

This product is non-dangerous goods, according to conventional chemicals transport storage this product with 25 L plastic barrel packaging, specifications 25×1. Should be placed in the shade. Contact with oxidants is strictly prohibited. Prevent high temperature sun storage temperature of 1~20℃, open packaging immediately after the use of sealed 24 hours must be used up.

[shelf life ] 6 months sealed.

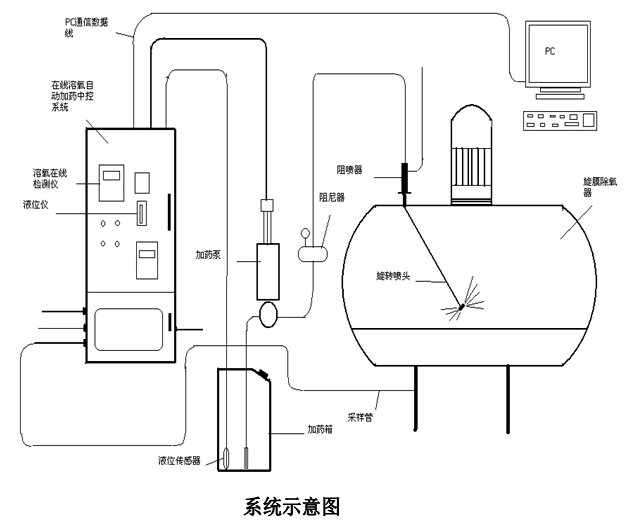

On-line Dissolution Oxygen Monitoring and Dosing Regulation System

[Performance characteristics]

It can automatically record the oxygen content curve in each period, realize 24 hours continuous monitoring, and automatically adjust the dosage according to the oxygen content.

In order to be more fair before the formal operation of the instrument manufacturers can send the instrument to qualified units for the school team.

To guide your employees in the operation of dosing and the use of metering pumps; and to provide an on-line monitoring dissolved oxygen meter for your use (Note: the property rights of dosing equipment and on-line monitoring system are owned by our company).

To guide your employees in the operation of dosing and the use of metering pumps; and to provide an on-line monitoring dissolved oxygen meter for your use (Note: the property rights of dosing equipment and on-line monitoring system are owned by our company).